Automotive Industry Braces for Impact, Actively Responds to COVID-19

China

The COVID-19 strain of coronavirus emerged in central China in December 2019. At the time, the Chinese auto market was about to report a second year of volume declines. After decades of reliable, robust growth, it was hard to accept that perhaps the industry’s best years would only now be seen in the back-up camera. The trade war with the United States was still lingering and a little-known virus was being reported with greater frequency.

After a decrease of 2.8% in 2018 followed by another of 8.2% in 2019, experts no longer questioned the likelihood of a third year of volume declines in the world’s largest car market; instead, the question being asked was how much it would decline. While the decrease in automotive sales was limited to 16.2% in January, the worst was yet to come. The usual post-holiday surge in retail sales did not occur and automotive sales plummeted 81.7% in February as compared to the same period one year ago.

United States

In the United States, new vehicle sales were 16.9 million in 2019, a decrease of 1.7% from 2018. Although not nearly the 8.2% decrease registered in China, sales were the lowest since 2014. Since most major manufacturers in the United States stopped reporting monthly sales results, discussing industry trends outside the quarterly cycle has been less straightforward. One estimate put U.S. new light vehicle sales at 1.1 million units for the month of January, a 1.0% increase from January 2019. In other words, light vehicle seasonally adjusted annualized sales (SAAR) for January 2020 was 17.1 million units versus 16.7 million units one year ago. The estimate was posted in the first week of February, without a mention of the coronavirus. Most other forecasts at the time were much the same.

In early February, the rest of the world still had not recognized the looming disaster in China for what it was, and certainly was not anticipating its spread beyond those borders.

Cox Automotive conducts a quarterly survey of dealer sentiment. More than 1,000 franchise and independent automobile dealers responded between January 27th and February 10th. At the time, dealers were optimistic about the upcoming spring selling season and prepared to commit to additional employees and technology enhancements to the cause. But if the survey had been administered just weeks later, as COVID-19 concerns spooked Wall Street and threatened consumer confidence, overall scores in the latest Cox Automotive Dealer Sentiment Index likely would have tumbled, according to Cox Chief Economist Jonathan Smoke.

High-Touch Industry

It only takes the modern assembly plant a few days to produce a vehicle from the time the first panel is stamped to the point the vehicle is tested and ready for shipment. Robots and automation are the rule in the press shop, the body shop, and even in the paint shop. But in general assembly, where life is breathed into the vehicle in the form of wheels, engines (now motors), transmissions, seats, and seat warmers… humans still rule. So, assembling cars is still largely a high-touch activity.

Although it can vary greatly depending on the type of vehicle (car versus truck), the annual volume, and the option content, there will be an average of 20 hours of labor invested in every vehicle produced, with most of it occurring in the general assembly department. Assuming no one individual touches the vehicle for more than 60 seconds (i.e. the takt time), a minimum of 1,200 people will have laid their hands on that vehicle before the consumer ever does.

The actual number is much higher considering many of the operations involve more than one employee, not to mention all the people that touch it upstream (suppliers) and downstream (dealers).

According to the World Health Organization, it is not certain how long the virus that causes COVID-19 survives on surfaces, but it seems to behave like other coronaviruses. Studies suggest that coronaviruses (including preliminary information on the COVID-19 virus) may persist on surfaces anywhere from a few hours up to several days. This may vary under different conditions (e.g. type of surface, temperature or humidity of the environment).

Moody’s Investor Relations

With all the people that come into contact with a vehicle during production, and given the amount of time the virus can survive on various surfaces, it is no surprise to me at least, that Moody’s Investor Services (Moody’s) has identified automotive suppliers and manufactures among the list of industries most likely to feel the economic impact from the COVID-19 outbreak. Richard Morawetz, a Moody’s vice president, writes “Companies’ ability to withstand the effects of the COVID-19 virus will depend on its duration, and we caution that as events unfold very rapidly on a daily basis, our assessment of exposure will change over time.”

At the writing of this report, most North American automotive manufacturers have voluntarily, or otherwise, closed their vehicle assembly operations for a period of two weeks. I tend to think it may be closer to six to eight weeks.

Although not based on any empirical evidence, I get the sense that we are at least 60 days behind the COVID-19 curve established in China, and China is only now trying to return to some level of functional normalcy.

When the automotive industry prepares for its annual two-week summer shutdown, there are weeks of planning that go into the process as the industry orchestrates an orderly shutdown. Without an orderly shutdown there is no orderly startup. The current shutdown was anything but orderly. In many cases, extraordinary measures were taken to keep plants running in order to compensate for other parts (e.g. China which accounts for 10% of automotive parts) of the global supply chain that couldn’t. As a result, even when the assembly plants are given the green light to restart production, the road back to full production will be rocky to say the least.

Moody’s Investor Services has identified automotive suppliers and manufacturers among the list of industries most likely to feel the economic impact of COVID-19 outbreak.

S&P Global Economics

S&P Global Economics (S&P), together with Moody’s are two of the major corporate credit rating services. S&P forecasts that U.S. gross domestic product (GDP) will shrink 1% in the first quarter followed by 6% in the second quarter. Economists consider two consecutive quarters of GDP declines to be a recession. S&P also reminds us that this downturn was a long time coming. COVID-19 is not the only cause for the downturn but one of multiple factors that have been building up to this moment. Among them, lower consumer spending, falling business investment, and unsettling trade negotiations to name a few. S&P believes U.S. growth could resume in the third quarter as long as the COVID-19 outbreak peaks in May.

S&P admits that in the current environment its forecast has a higher than normal degree of uncertainty. From Hilco’s perspective, the fact that many automotive plants will be closed due to COVID-19 will have even more of a negative impact than implied by the S&P’s 6% shrink forecasted for the second quarter. Add to that a significant slowdown in demand because consumers will have little or no appetite for buying cars over the next two to three months, and we anticipate the impact of the crisis on the industry to be worse than many anticipate.

The Response

When faced with adversity in the past, the Automobile industry has demonstrated its willingness to respond. Today is no different. Fiat Chrysler Automotive (FCA) is now in the process of converting one of the group’s plants in Asia to produce face masks for healthcare workers and expects to reach a target of one million masks per month in coming weeks. FCA and Ferrari are also in talks with Siare Engineering, Italy’s biggest ventilator manufacturer, to help it double production of the life-saving machines which are urgently needed in the COVID-19 crisis. Ford Motor Company, has also announced plans to manufacture a number of devices and tools used by healthcare workers treating COVID-19 patients, including plastic face shields, powered air-purifying respirators, and a simplified respirator.

GM Financial, General Motors’ captive finance division, is giving dealers a break on some floor-plan payments to help mitigate the effect of COVID-19 on business operations. More specifically, GM Financial is temporarily waiving curtailments a dealer owes to pay down floor-plan inventory and is guaranteeing dealer dividend payments will be consistent with the previous month (i.e. before the sales decline). For consumers, GM is offering zero percent financing for 84 months and 120-day payment deferrals for customers with outstanding credit. GM is also lending its logistics, purchasing and manufacturing expertise to Ventec Life Systems to help increase production of respiratory care products such as ventilators. The partnership is part of StopTheSpread.org, a coordinated effort of private companies to respond to COVID-19.

Mark Sheffield knows a thing or two about what to do in a situation like this. He’s a U.S. Army Veteran and former [motorcycle] dealer principal who currently facilitates multiple 20-groups for Spader Business Management. Sheffield observes that we are accustomed to seeing problems in the distance leaving us time to react, but that COVID-19 swooped in from the periphery and is catching many of us unprepared. He suggests, “take the perspective that COVID-19 is here and is going to be hanging out for a while.”

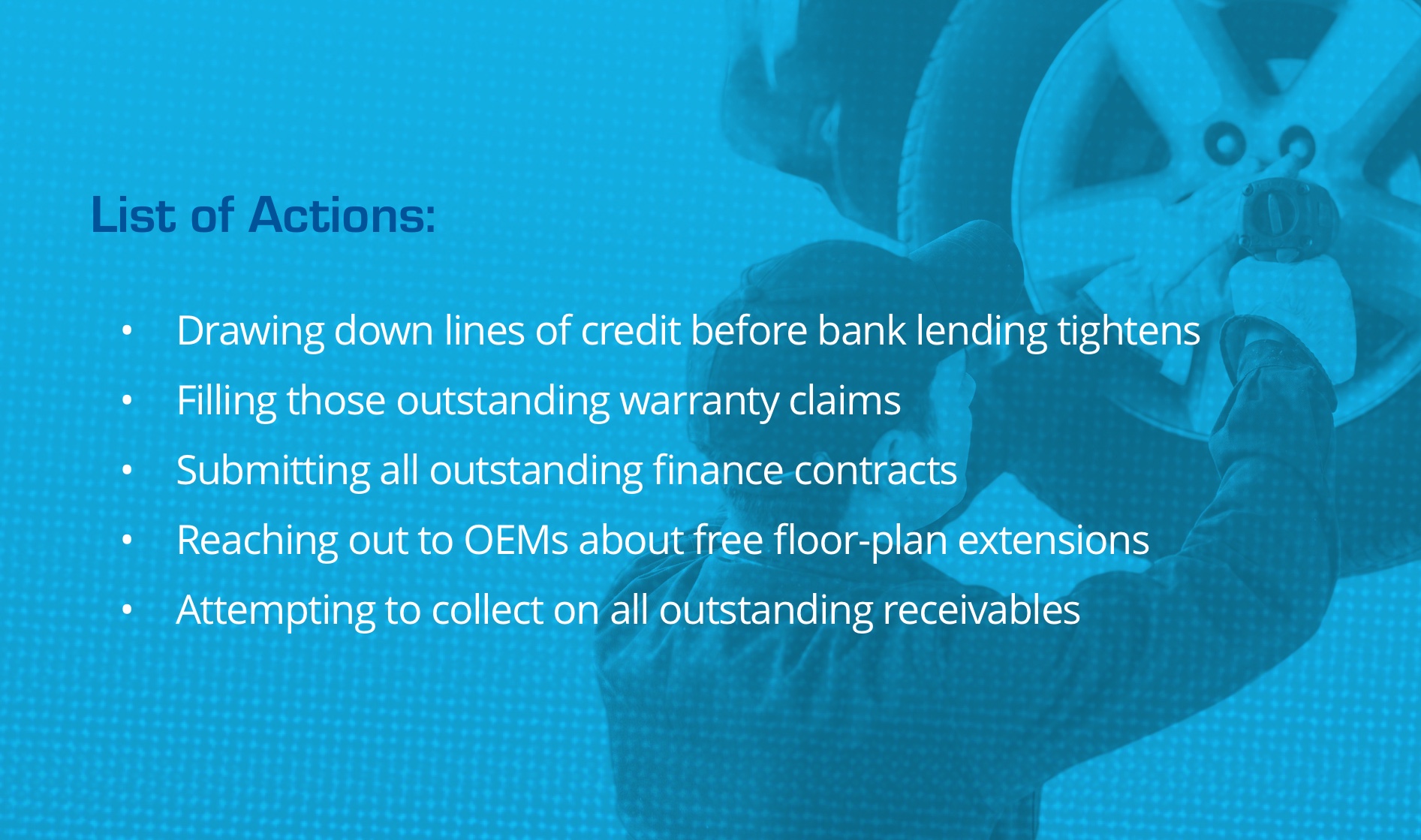

In a recently published article Sheffield provides a thoughtful list of actions that business owners can consider including drawing down lines of credit before bank lending tightens, filing those outstanding warranty claims, submitting all outstanding finance contracts, talking to your floor-plan lenders about limiting curtailments, reaching out to the OEMs about free floor-plan extensions, and attempting to collect on all outstanding receivables.

We at Hilco could not agree more with Mr. Sheffield. For our part, Hilco Global stands ready to help. We have extensive experience in monetizing assets. Hilco Global offers asset monetization through a variety of disposition methodologies, including on-site, online and live webcast auctions, and private treaty negotiated sales. In time-critical situations, where cash is needed quickly or when an auction may be disruptive to a business, Hilco Global often acquires the assets to be monetized using its own capital. Further, Hilco Global may act as a principal and acquire a business in its entirety. When seeking to maximize realized value for tangible and intangible assets, Hilco Global has extensive experience and can tailor a strategic solution and deftly manage the entire monetization process from start to finish.

ABLs and manufacturers alike have achieved a high level of success across numerous industries in partnership with Hilco Valuation Services based upon our disciplined process, industry leading bench strength, systematic and collaborative approach. This success is a testament to our commitment to excellence. By understanding past cycles and performance, documenting historical data points across the sectors and industries, and continuously exploring and assessing the path that is being paved ahead, Hilco Valuation Services consistently delivers reliable, accurate and actionable valuations for our valued customers.