Shifting Housing Preferences and Online Shopping Growth Fuel Demand

In this article, we take a look at how pandemic-driven changes in consumer preferences and behavior are impacting demand across numerous forestry product markets and how an industry challenged by continued resource limitations is responding.

Last summer, just a few months into the COVID-19 crisis, Hilco published an article focused largely on the topic of how the designation of construction as an essential service across much of the country was helping to sustain the U.S. lumber market. We also discussed how unprecedented demand for toilet paper at the time (which sounds almost comical now) was serving to bolster pulp prices. Slightly over a year later, as many of the restrictions imposed during the pandemic have been lifted or minimized, we revisit the market to see how things have evolved.

For starters, construction demand continued to escalate throughout the pandemic with many homeowners deciding to renovate and update their existing homes and numerous others, particularly renters and owners based in large urban areas, deciding to make a move to outlying suburban areas and secondary markets. This trend was fed by two primary factors, both succinctly captured in a Washington Post June 1, 2020, article about reconsidering city living: “Two months of sheltering in place in their rented two-bedroom apartment gave the pair some unexpected clarity about what was important to them. And new policies letting them work remotely indefinitely at their respective jobs gave them an opportunity to do something about it.”

Since that time, with a number of big tech and other firms indicating that they will be shifting to a primarily ‘work from wherever you want’ model, it is becoming increasingly apparent that the current housing boom is likely to last for a number of years. As REI President and CEO Eric Artz told employees in a video call last summer, “This year has shown us our home is not a building. Our home is wherever we find ourselves doing our best work.” Even for workers whose employers mandate some days in the office each week or month, moving to less expensive and more expansive housing that can accommodate a home office and other flex space on the outskirts of their own metropolitan area has become an attractive commute proposition based

on the lifestyle benefits.

Why do we foresee such an extended timeframe for expanding home construction? First, housing capacity in many of the most desirable (AKA: affordable and land abundant) markets, including the states of Florida, Georgia, Tennessee and Texas, cannot currently meet demand. Furthermore, there is a currently a shortfall of both labor and materials to facilitate construction. As a result, we can expect to see developers in these relocation markets ramp up projects in the coming months and years to meet demand as resources become more readily available. Second, while some making the move will be remaining with their current employers who support the work remotely lifestyle, others will be leaving less flexible employment environments and seeking out new positions with more progressive companies. In both cases, timelines for these transitions will vary based on factors such as employment bonus and vesting timeframes, existing lease terms, back-to-school start dates, as well as the time it takes to find a suitable position and either temporary or permanent housing in a new market.

Prior to the pandemic, the lumber market had been generally depressed for over a decade. As a result, the market saw numerous longstanding sawmills cease operations, with many closing in just the past two or three years after holding out for as long as economically feasible for a turnaround that ultimately came only after their facilities shuttered. The gap created by these closures created significant strain on the industry. As a result, when Americans started to push forward with plans for their new at home lifestyles beginning just a couple of months into the COVID-19 crisis, demand jumped an unprecedented 20% virtually overnight and product at lumberyards around the country began turning over at record rates.

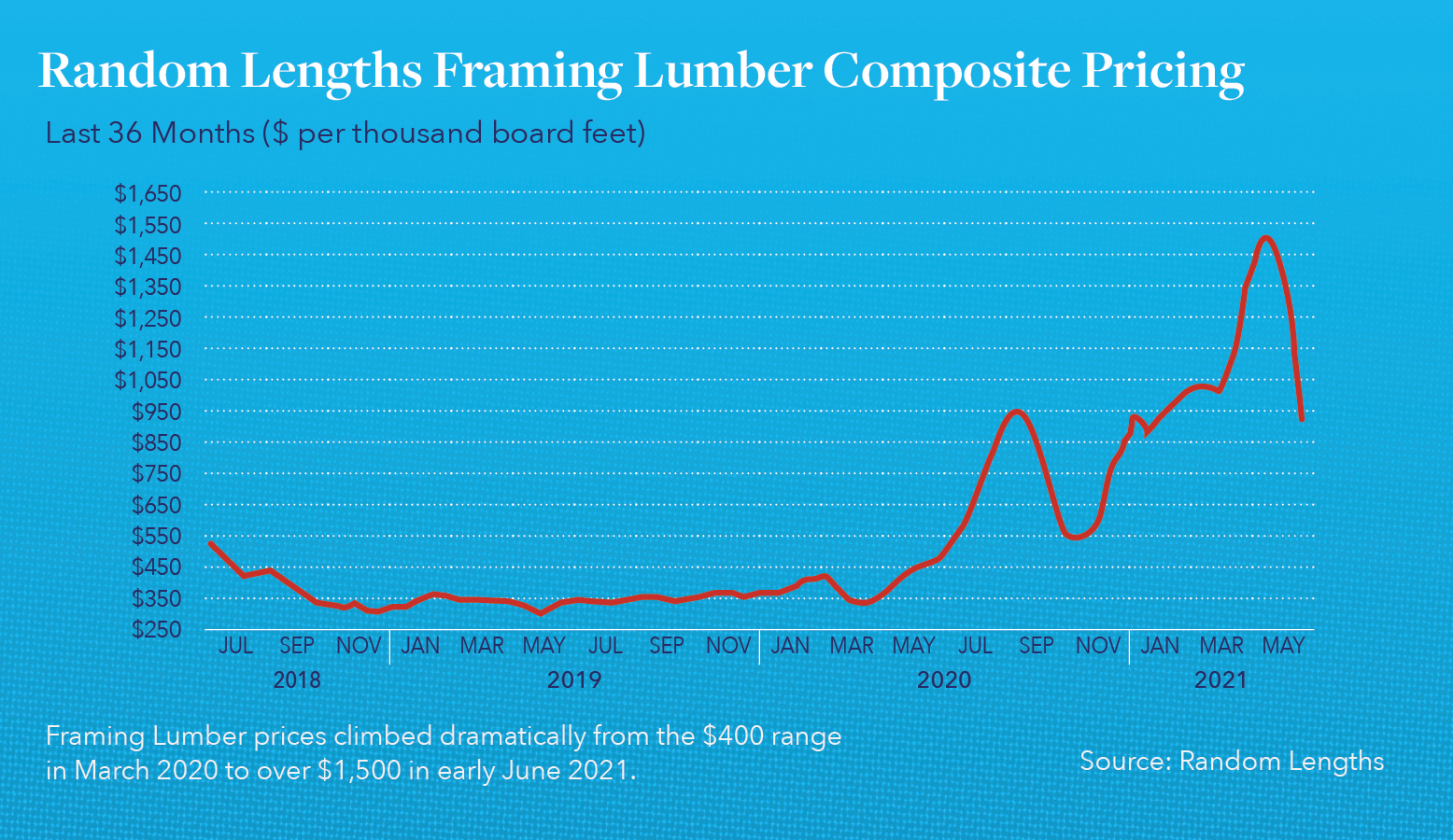

Lumber prices across the U.S. were directly and significantly impacted by these developments with prices climbing from the $400 per thousand board feet (MBF) range in March 2020 to over $1,500 per MBF in early June 2021. While these have since normalized to some degree, pricing on June 30, 2021, still represents an increase of more than 100% as compared with early 2020 pre-pandemic levels. There will, without question, be a supply response as some old, previously shuttered and new mills come online to meet demand. Additionally, as government stimulus runs out, the mill labor force will return as well. Along with this supply increase/response, we expect to see a further correction in pricing, down to a range likely between $500 and $800 per MBF. We do not, however, foresee a further drop to pre-COVID levels of $200-$450 per MBF for at least a few years based on the prospect of continued strong demand.

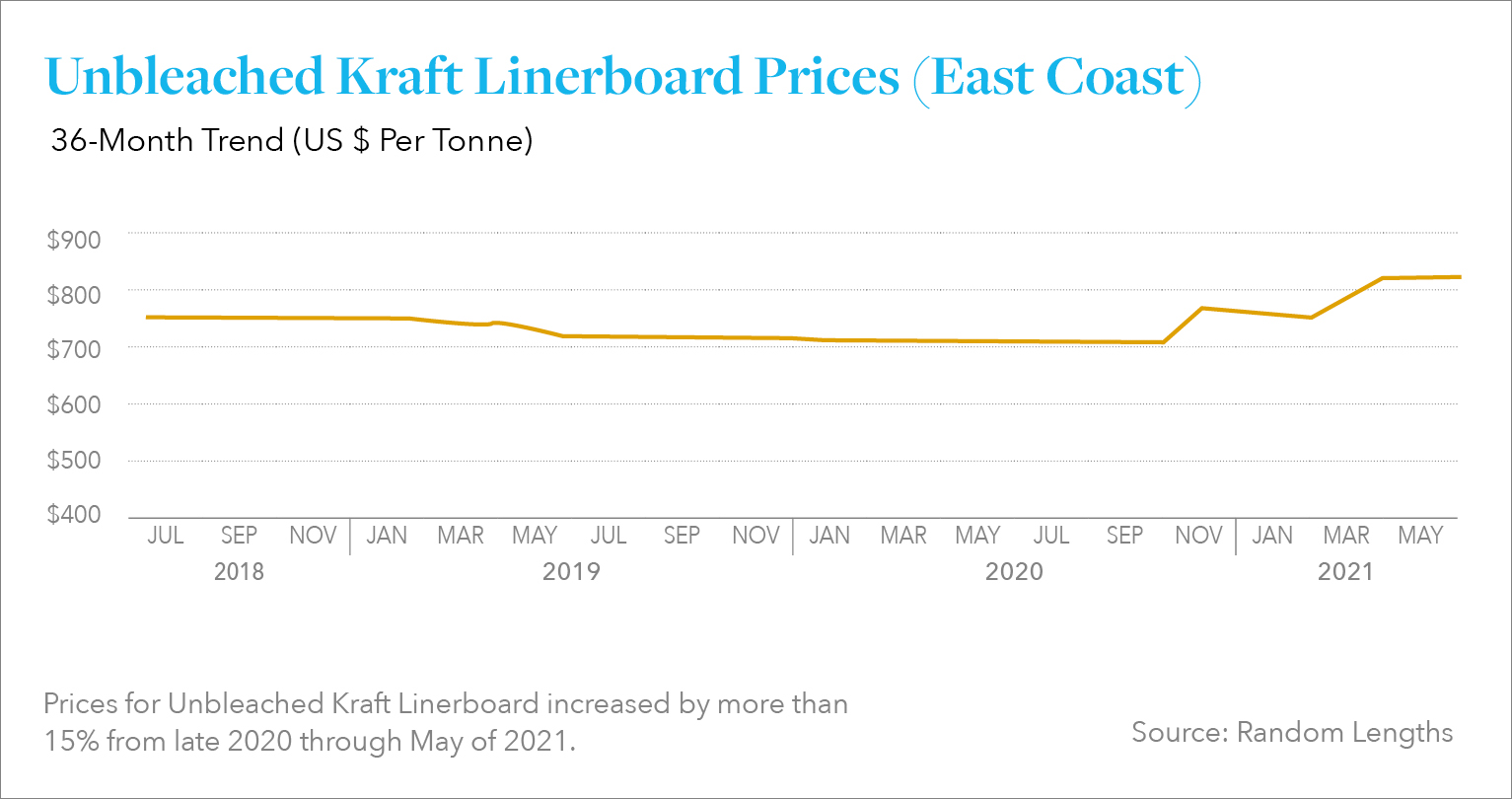

Another market that has been positively impacted by changes that resulted from the pandemic is the containerboard market. Five main providers control 80% of containerboard production in the U.S., which has provided for significant pricing power and their ability to steadily raise prices over time. Over the past few months, alone, prices have increased by between $70 and $80 per ton. Continued strong demand for containerboard-based boxes has contributed to this pricing strength, with significant sales volume coming from the steady grocery channel and being further boosted by continued acceleration in the adoption of online shopping—which now accounts for approximately 15%-20% of total sales. Even as brick and mortar retailers have reopened, we are seeing the stickiness of the shift to online buying and most analysts seem to agree that many consumers will never return to their full pre-COVID in-store buying regimen. The rebound in industrial production that we have seen over the past six months has also contributed positively. Over the past decade, demand for containerboard has increased by an average of only about 2% annually, but is now exceeding that figure based on these pandemic period developments.

The recent acquisition of forestry giant Domtar and its 13 operational mills for U.S. $3 Billion by British Columbia’s biggest pulp-and-paper producer, Paper Excellence, illustrates how the industry’s long-term market potential is now being viewed. In May, the company’s CEO Joe Ragan called the move a “natural fit” as it seeks to gain a stronger foothold in the U.S. Pulp coming from the Domtar mills will also likely make its way to Asia over time, given that the recycled fiber infrastructure on the continent lags that of many other regions. Presently, pulp produced around the world is sent to countries including China and Indonesia to fulfill growing demand based on the explosive growth of online shopping in those and other Asian countries.

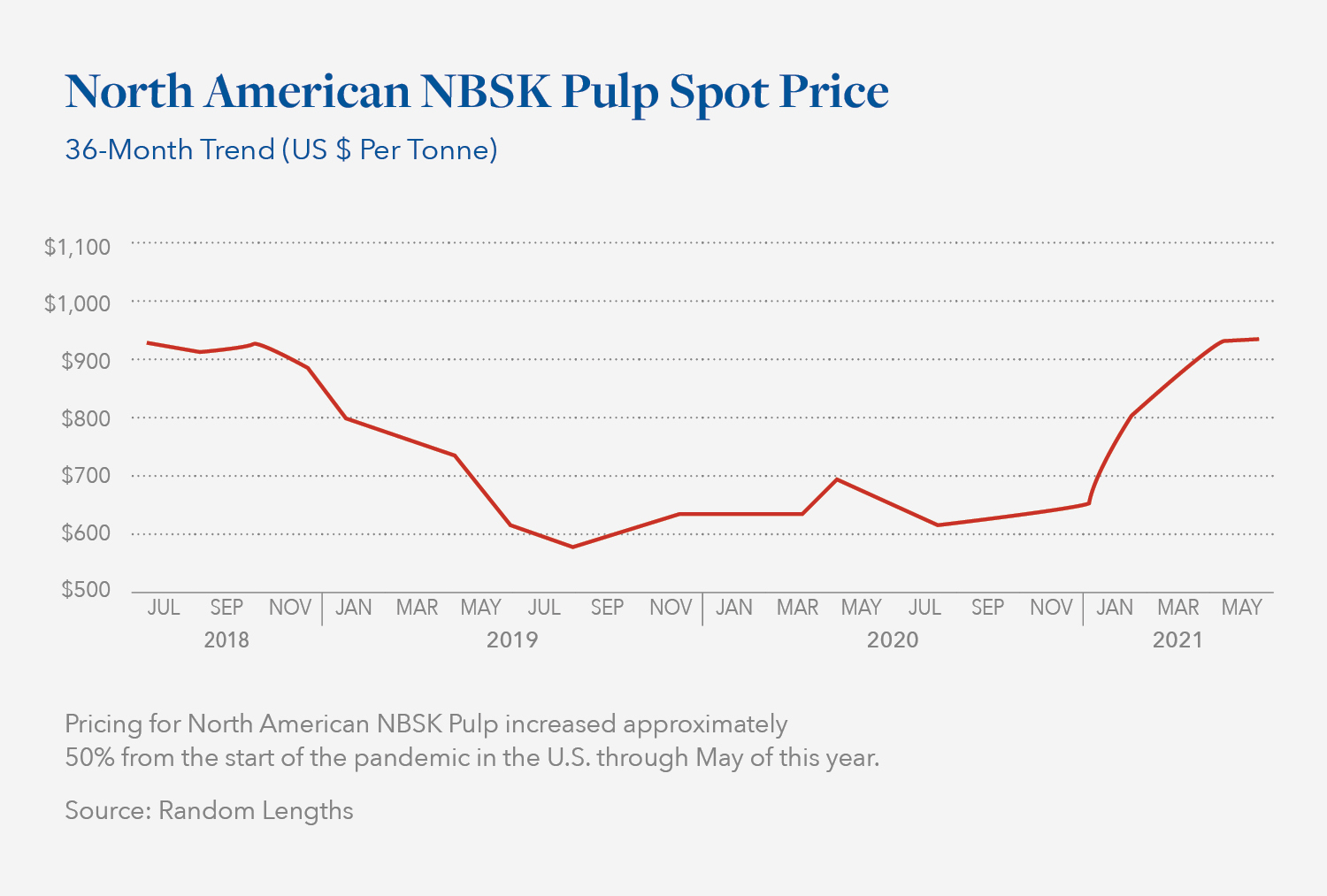

As highlighted in our article last summer, pulp received a brief but notable boost from consumers’ largely irrational toilet paper and paper towel hoarding behavior early on in the pandemic. Historically, the majority of pulp produced has been utilized in the production of papers intended for writing, copying, print advertising and other purposes. While COVID-19 mandated closures of offices nationwide dramatically diminished demand for these papers, their use had been steadily dwindling over the past decade as digital technologies were more broadly adopted. Accordingly, very few new pulp mills have come online in recent years. They are expensive to build, run and maintain, making them a highly capital-intensive investment proposition. As a result, there have been some significant supply shortages and a rather significant bump in pricing as strong demand for containerboard has pulled along the associated demand for pulp.

Conclusions

We have seen values across the board in the forestry industry increase over the past year and expect strong demand to continue. Given the ongoing volatility of pricing in the market, the biggest risk moving forward may well be for distributors who sit squarely in the middle of the supply chain. A sudden, unexpected drop in prices could, for example, dramatically impact large providers of lumber to new home builders and others. Accordingly, we advise lenders with exposure here and across the industry to closely monitor borrower inventory turnover rates to observe how quickly they are working through inventory on hand and minimize the potential for getting caught on the downside.

Hilco continues to recommend normal levels of valuation monitoring for the industry, and welcomes the opportunity to answer any questions or address any concerns you may have pertaining to specific exposure within your portfolio. As always, we are here to help during

this volatile period!

Hilco Valuation Services

is the leader in valuation for the forestry and lumber industry, having delivered more than 500 forestry and lumber appraisals, with asset values ranging from $500 thousand to $1 billion. As one of the world’s largest and most diversified business asset appraisers and valuation advisors, we serve as a trusted resource to companies, lenders and professional service advisors, providing value opinions across virtually every asset category. Hilco Valuation Services has the ability to affirm asset values via proprietary market data, direct worldwide asset disposition and acquisition experiences. Access to this real-time information, in contrast with the aged data relied upon by others, ensures more reliable valuations for our clients, which is crucial when financial and strategic decisions are being made.