Intermodal Chassis Market Demonstrates Pandemic Period Resilience

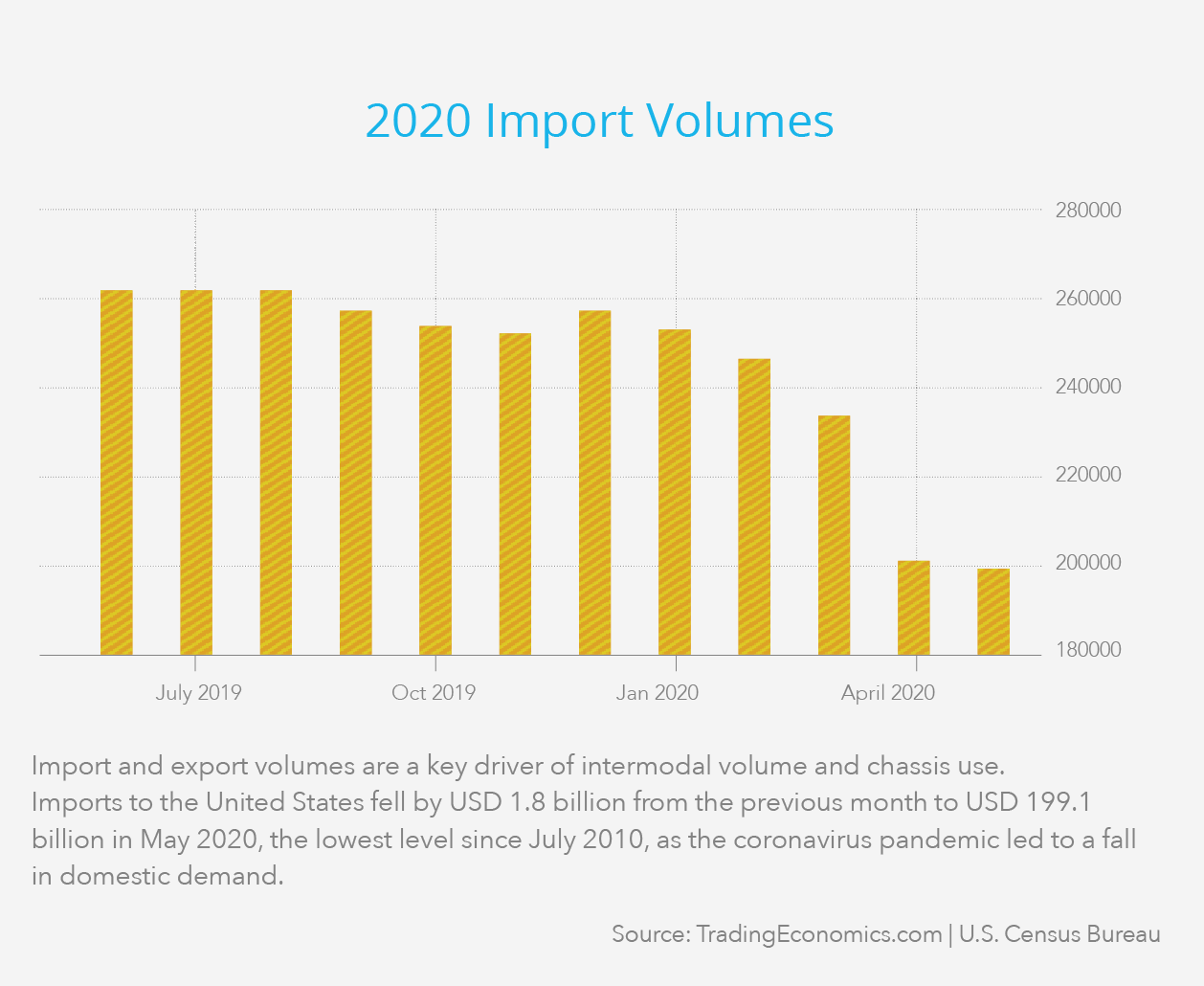

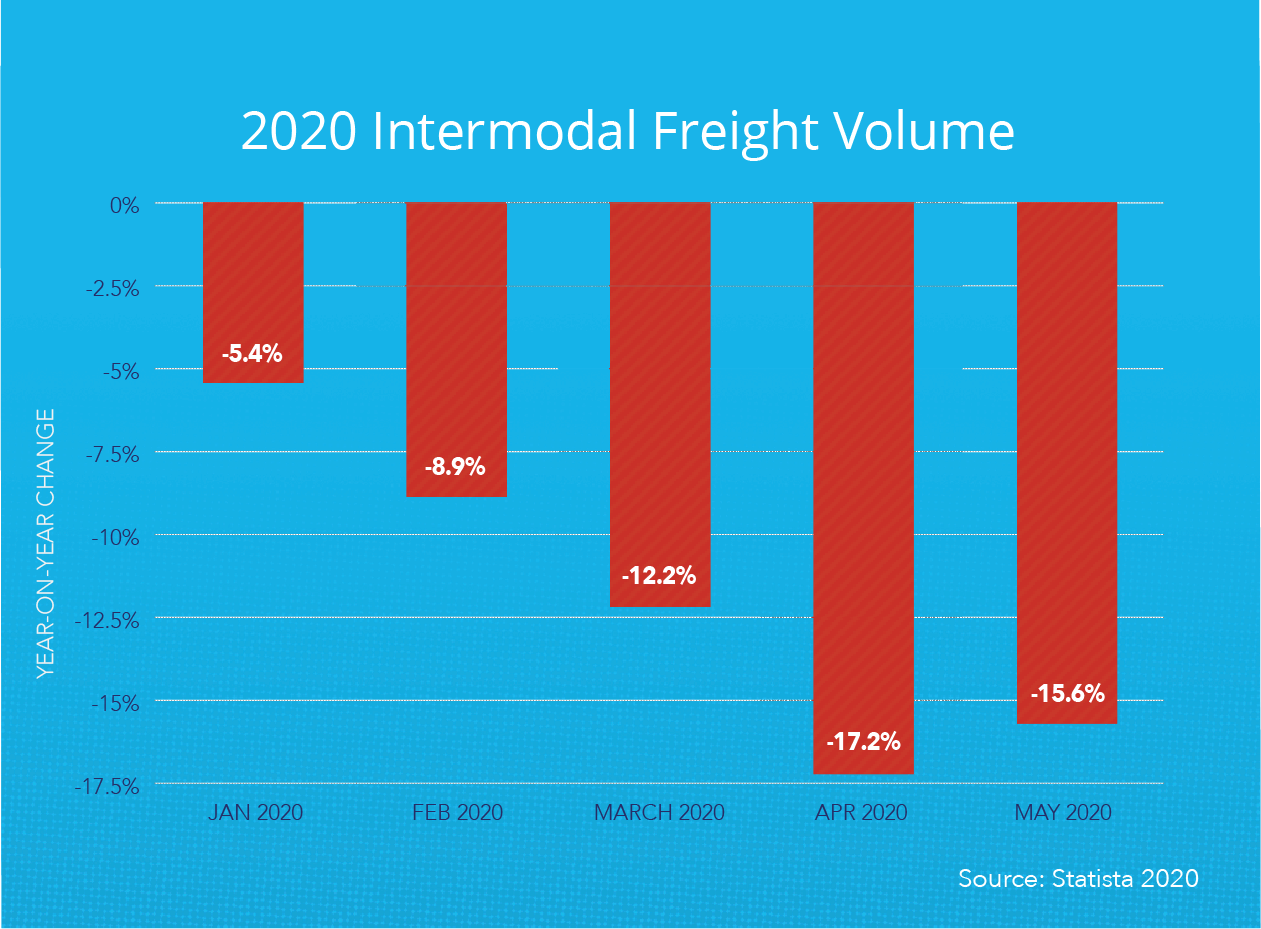

In this article we take a look at the impact of diminished import/export volumes on the chassis segment of the intermodal industry, how providers and end-users have responded during the current crisis, and the likely path forward for industry recovery over the balance of the last two quarters of this year and into 2021.

Overview

On a global basis, 95% of all manufactured goods are at one point transported in a container. The intermodal industry connects a number of freight stakeholders, including third-party logistics providers, motor carriers, railroads, ocean carriers and container ports. According to the Intermodal Association of North America (IANA), annually, the $40 billion North American intermodal market, alone, moves 34.5 million domestic and international containers of consumer, industrial bulk, agricultural and other goods via a fleet of more than 700,000 chassis.

Chassis are the literal backbone of intermodal road transport, as they provide the framework on which shipping containers rest during their travels between intermodal terminals and shipping facilities. Owned by leasing companies, motor carriers, railroads, shippers and some steamship lines, chassis come in a variety of sizes and configurations, each designed to accommodate the size and weight of specific ocean/marine, domestic and specialty containers.

Durable and reliable, container chassis have an extensive life span. In fact, the average age of chassis in use within North America today is estimated at approximately 18 years, with the majority expected to provide a total useful service life of between 20-25 years or longer. Because a chassis is essentially a frame with suspension and axle systems, wheels and tires, brakes, and a lighting/electrical system, fleet upkeep for conventional and pool providers is relatively simple. Other than visible wear, new, used and rebuilt equipment often look much the same at a glance. Updated features such as LED lights replacing traditional bulbs, as well as upgraded tires with automatic tire inflation, ABS, weight sensors and GPS tracking systems, are often the key differentiators. While these enhancements clearly add to operational safety and efficiency, chassis at both the beginning and end of their useful lives serve a valuable role and can deliver excellent returns when properly managed and maintained.

To be certain, the real innovation taking place in the chassis market today is software-driven. Knowing precisely where the fleet is and how to pick it up efficiently, is becoming a critical aspect of overall fleet management as it empowers quicker action at lower cost during everyday business operations as well as in valuation/liquidation scenarios. We have seen increased receptivity among lenders to loan facilities associated with aging chassis fleets, particularly as they have observed key players investing significantly in their respective aging fleets. Two cases in point: 1) DCLI’s recent investment of over $80 million in upgrading its chassis pools across the country with an emphasis on converting to radial tires and; 2) American Intermodal’s (AIM) effort to enable all of its chassis with the latest GPS positioning technology.

Software-driven GPS innovation is being deployed to track and deliver real-time data, adding greater efficiency for managing new and retrofitted chassis fleet assets across their lengthy lifespan.

Source Image: CloudHawk®

Investments such as these make sense when considering that their lengthy life expectancy enables chassis owners to effectively amortize their investment over a period of many years, during which their fleets typically deliver a consistently healthy cash flow and maintain strong, tangible hard asset values. When not in use, many chassis are stored offsite and can be utilized as needed to cover peak holiday demand. Chassis are typically fully rebuilt to modern standards at end of their useful life, or when minor damage has occurred. Hilco values these renewed assets according to the rebuild date rather than their true historical age, and our accuracy in valuing and effectiveness in monetizing these unique assets is unsurpassed in the industry. In cases where disposition of either an entire fleet or large quantities of chassis assets are involved, Hilco leverages a “hybrid in-place” model to ensure maximum residual cash flows for current leases/contracts, while achieving strong market values for idle equipment via timely marketing and sale.

Historical Perspective

Steamship lines, themselves, had historically been the primary owners of container chassis since Intermodal’s inception. The economic ramifications of the 2008 financial crisis changed that, however, leading to a renewed focus on core shipping services and divestiture of chassis assets by the lines, who no longer wanted responsibility for the associated investment, storage, repair, and logistic costs. With an annual expense of about $1,000 per chassis, these costs were quite significant based on the fleet size of most shipping lines. Over the past decade, this industry-changing shift has given rise to the predominant chassis lease and chassis pool system now in place in the U.S.

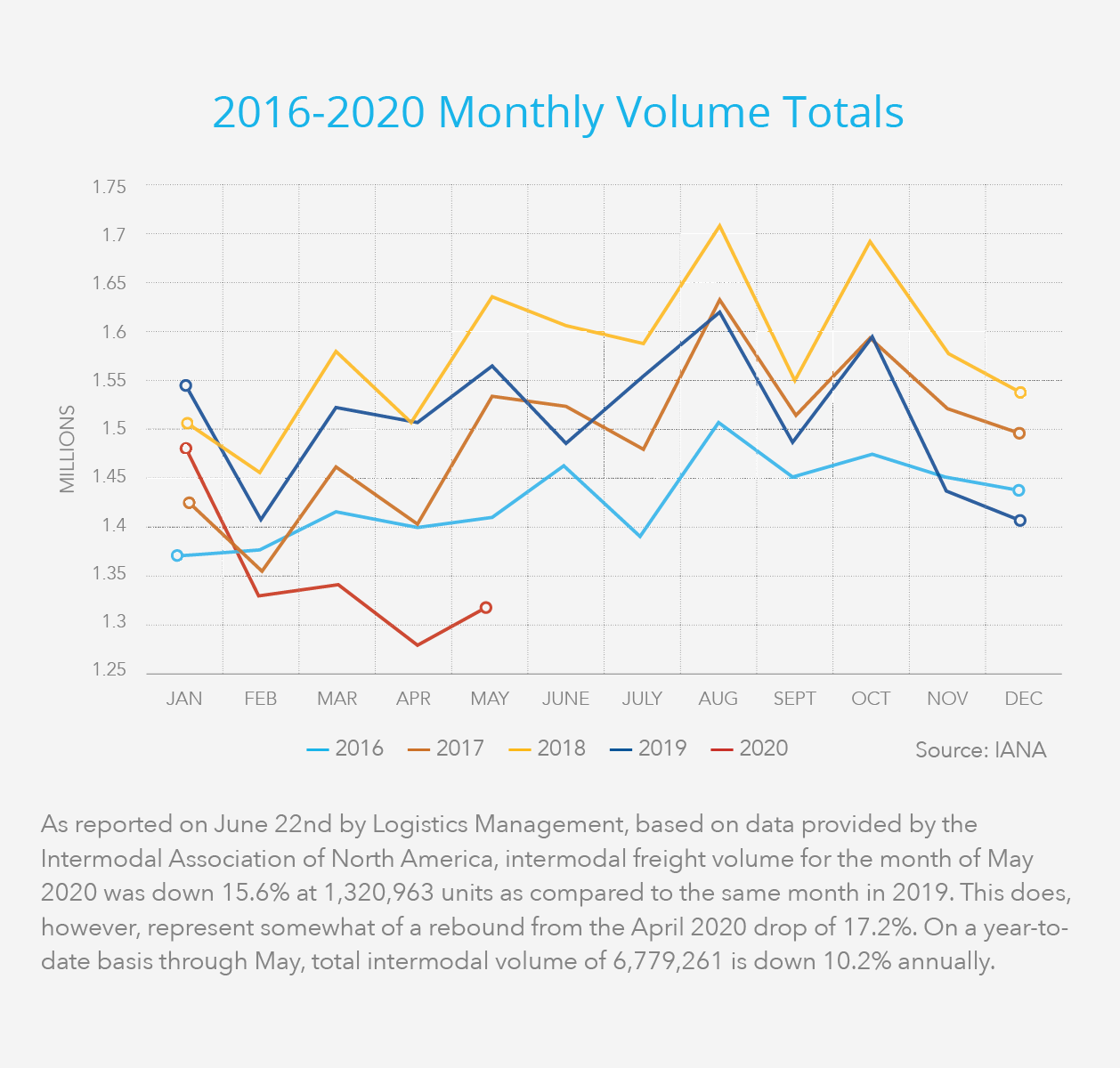

After faltering during 2016 in conjunction with the bankruptcy of shipping giant Hanjin – which threw ports and retailers around the world into turmoil as massive container ships were marooned and merchants worried whether goods would ever reach their shelves – the intermodal and chassis markets stood the course in 2017 and achieved record numbers in 2018, with inbound international and domestic container volumes rising by 6.5% and 5.5% respectively.

2019 was a year of modest growth in container trucking, with U.S. container imports increasing only 1% over 2018 levels and chassis volume falling slightly. Most chassis providers chose to refurbish existing assets rather than purchase new equipment in 2019, in large part because new chassis are primarily manufactured and sold by two providers located in China and would have been subject to the 25% tariffs imposed by the U.S. during the trade standoff at the time. Recognizing the pitfalls of such susceptibility to its business model, China’s CIE Manufacturing (formerly CIMC), the world’s largest producer of new chassis, relocated its production facility in Q1 2020 to the U.S. from China. Also, of note in 2019, DCLI purchased part of the domestic pool chassis business from TRAC International (TRAC), further solidifying its ability to provide the 53-foot chassis utilized exclusively in the U.S. Puerto Rico and Caribbean, per the Merchant Marine Act of 1920, which regulates commerce in U.S. waters and ports.

Current Market

As 2020 began and a U.S./China trade deal was signed, chassis providers were hopeful for a solid start to the year, but COVID-19 threatened to prevent that. While the domestic pool helped support the market early on, the onset of COVID 19 has certainly presented the industry with numerous challenges. To their credit, TRACS, DCLI, FLEXIVAN and other key industry players took proactive steps from the onset of the crisis to ensure that field maintenance and repair teams remained operational at rail, marine and other intermodal locations and that road service was readily available for any chassis equipment incidents that might occur during the unusual operating conditions.

From a volume and operational standpoint, the decline in traffic based on the pandemic has been less significant than we had anticipated. While March through early May chassis market performance was down and shipping alliances, as reported by Container News in June, have announced some third quarter blank sails despite evidence that the U.S. economy is beginning to see demand recover– one major provider has informed Hilco that their last week of May was in line with the same week in 2019.

Given chassis’ infrastructure-orientation, customers want and need to make sure they have chassis when and where they need them as markets recover. As a result, pool participants are continuing to make their monthly payments to ensure priority access, as are contract holders, who are keeping equipment on-hand so it is available as needed. We are hearing from providers that even customers who are having difficulty making payments have, for the most part, asked for some form of revised terms rather than terminating their relationship and their future access to those chassis assets altogether. We believe these actions strongly suggest that that those across the industry expect a return to more normalized volume in the months ahead. It bears noting that for some, such as UPS and USPS who have seen strong demand and associated volumes continuously through this period, maintaining those contracts has essentially been business as usual.

Outlook

Based upon the above referenced feedback from the market, as well as our own and other market intelligence, Hilco expects chassis utilization to ramp-up in conjunction with consumer spending levels and the associated global and domestic movement of goods in Q3 and Q4. We see this likely resulting in performance for 2020 as a whole just slightly below 2019 levels. Since forecast volumes for 2020 were relatively flat, actual results may be in line with expectations, setting a pace for modest growth moving into 2021.

We expect strong interest in acquiring quality used chassis moving past the peak pandemic period. Much of this will likely be driven by a desire to add capacity to chassis pools in order to service existing customers while also being able to capture new, large accounts by guaranteeing volume access. Because chassis are rarely available on the used marketplace in bulk quantities, as growth returns, we see the potential for increased large-scale purchases of chassis via competitive acquisitions as well as a renewed interest in made-to-order, new chassis purchases directly from the manufacturers.

We have been working closely with leading providers and communicating regularly with numerous stakeholders across the industry throughout the current crisis. For ABLs with questions or concerns regarding specific exposure within their portfolio at this time, we are here to help and encourage you to reach out to us for any perspective and guidance pertaining to chassis fleet valuation considerations, acquisition, disposition and other matters.

HILCO GLOBAL IS ONE OF THE WORLD’S LARGEST AND MOST DIVERSIFIED BUSINESS ASSET APPRAISERS, VALUATION ADVISORS, AND MONETIZATION EXPERTS.

A trusted resource to companies, their lenders and professional services advisors, Hilco Valuation Services provides value opinions across virtually every asset category. Our extensive experience in valuing and monetizing chassis assets is unsurpassed in the industry, with our valuation and M&E teams working closely together to deliver maximum accuracy and efficiency on behalf of our clients. With

a dedicated team focusing on truck, trailer and chassis fleets, we have performed valuations on well over

1 million assets across transportation and logistics, covering $2 billion in deployed capital. Hilco’s track record in the liquidation of fleet assets for maximum valuation based on its understanding of realistic value and real challenges to an actual orderly liquidation process, is highly regarded across the industry. Hilco Valuation Services has the ability to affirm asset values via proprietary market data and direct worldwide asset disposition and acquisition experiences. Access to this real-time information, in contrast with the aged data relied upon by others, ensures our clients more reliable valuations, which is crucial when financial and strategic decisions are being made.